Production

Home > The Hydrogen Story > Production

Menu

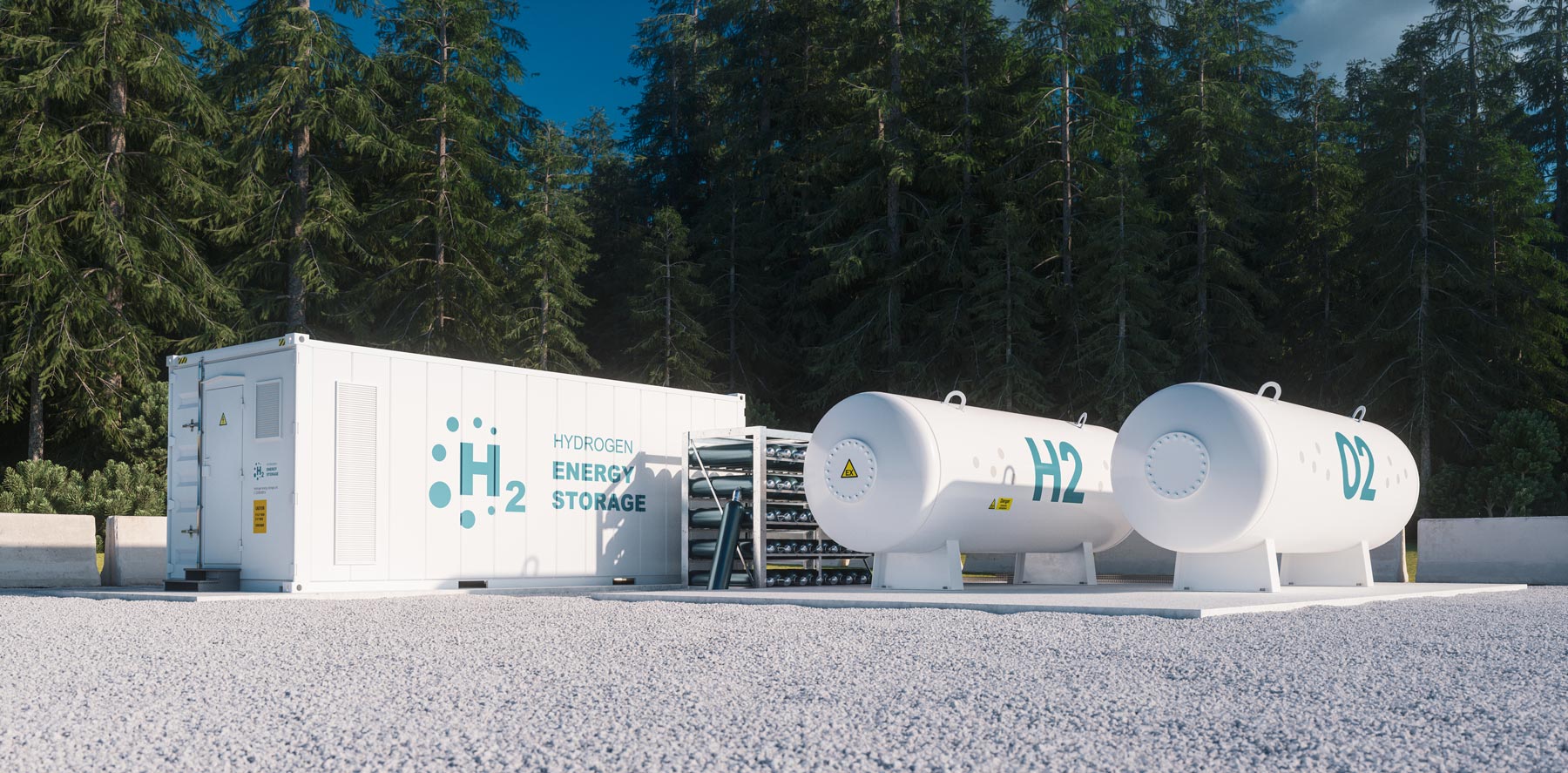

There are two main hydrogen production routes:

Electrolysis – Commonly referred to as “green hydrogen”, hydrogen production via electrolysis uses electricity to split water into hydrogen and oxygen. No greenhouse gas emissions are produced, although there may be emissions associated with the electricity generation. Electrolysers can help to balance the electricity grid by rapidly increasing or decreasing demand to ensure supply and demand are equal.

There are other hydrogen production routes such as:

Gasification with CCS – Gasification occurs when a hydrocarbon rich feedstock is heated to a high temperature to produce a syngas. This syngas contains high levels of hydrogen as well as other contaminants which can be removed if necessary. Coal and biomass can be used as gasification feedstocks with the potential for negative lifecycle emissions when biomass gasification is combined with CCS.

Nuclear enabled – Nuclear power plants can produce zero emission hydrogen at scale in a variety of ways. This includes electrolysis, steam electrolysis using waste heat and thermochemical water splitting. Small modular reactors can also be utilised to produce emission-free hydrogen. The Nuclear Industry Council (NIC) estimates that nuclear could produce 75TWh of green hydrogen by 2050.

Orsted, ITM Power, Phillips 66 and Element Energy have come together to develop Gigastack, a project to demonstrate the benefits and potential of renewable hydrogen derived from offshore wind.

Since 2020, the project team has been developing a blueprint for deploying scalable electrolyser technology across the UK with a 100MW electrolyser front-end engineering design (FEED) study. This has included the next generation of polymer electrolyte membrane (PEM) electrolyser system at the 5MW scale; and expanding ITM Power’s electrolyser manufacturing capacity by moving to a new site and installing new semi-automated manufacturing equipment.

During this process the Gigastack team has explored potential challenges such as: accessing a water supply in an industrial area; integrating into a high-voltage electrical substation a few miles away; integrating pipework into an operational refinery; and planning and permitting for a first-of-its-kind renewable hydrogen project.

The team will now focus on the key areas for the next phase of project development, with a technical concept ready to take to a detailed design phase and be used for future energy integration projects.

The project received £7.5M as part of BEIS’s Low Carbon Hydrogen Supply Competition and is expected to publish its final report in the summer of 2021.